Thank you for your interest in the PHYMAT far infrared heating pad.

PHYMAT Infrared Heating Mat is one of the best Infrared Mats on the market. Although with the same quality and efficiency, the PHYMAT heating pad is much cheaper than other brands. Why PHYMAT Infrared heating pads are sold at a much lower price? This question is considered and wondered by many consumers. So, today, I’d like to explain and answer this question.

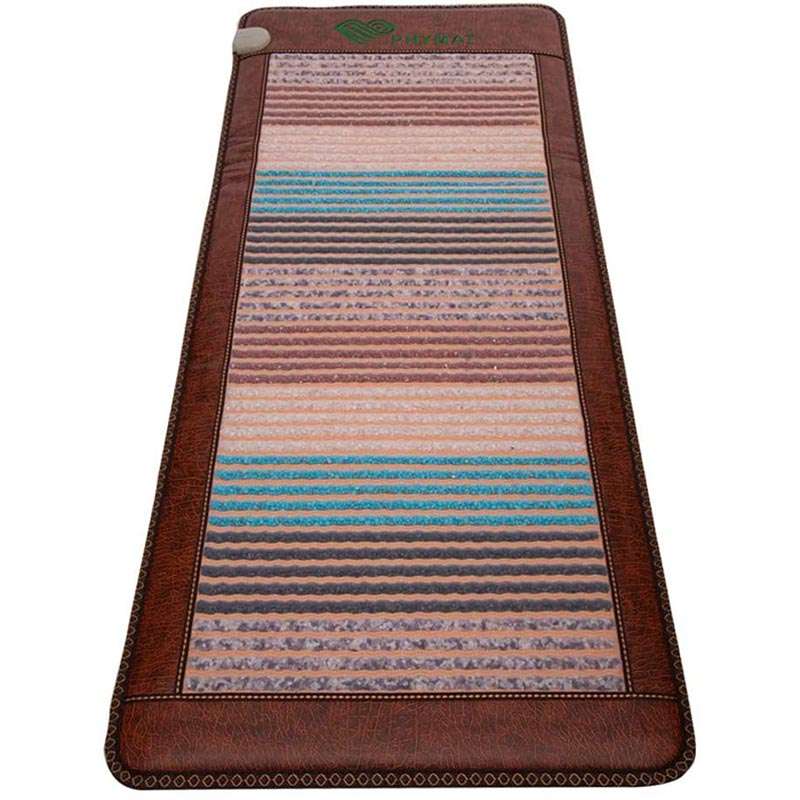

PHYMAT® is a registered trademark brand in the United States. We’re a factory-based manufacturer of rich far-infrared hot stone heating pads with well-equipped testing facilities and a strong technical force. We produce far-infrared heating pads of jade, tourmaline, amethyst, and other precious stones in a variety of sizes. In addition, we also produce other products filled with jade, tourmaline, amethyst, and other crystals, such as belts, vests, pillows, etc.

We build a factory in the raw material production area to produce PHYMAT brand hot stone heating mats. Shenyang, China, is not only the original place of some types of gemstones and crystals, but also the pioneer manufacturing base of Korea FIR mat.

Gemstones and Crystals Used for Infrared Mat PHYMAT Infrared Mat Factory

The factory of PHYMAT® is located in Shenyang – a city in northeast China. With a wide range, good quality, reasonable prices, and stylish designs, our products are extensively used in health care and other industries world around.

The establishment of a factory in the place of raw materials ensures that the hot stone heating pads of the PHYMAT® can select high-quality jade, tourmaline, obsidian, turquoise, amethyst, and other gemstones to produce hot stone heating pads. At the same time, it also greatly reduces our raw material procurement and labor costs in the production process. In addition, we adopt online sales, which also greatly reduces our operating costs. Based on these two main measures, PHYMAT can provide you with more preferential prices while ensuring product quality.

Whatever, let’s see some details of the production process.

Production details of infrared mats

- Raw Material Tailoring Procedure

- Cutting PU Leather

- Artificial Sewing Process

- Affixed Tourmaline Stones

- Edge Sewing Process

- Electrical Test of Heating Mat

- PHYMAT EMF Testing

- Packing the Mat into a Box

- Strapping the Carton Strongly

- High-quality raw materials applied: jewelry-grade certified natural gemstones and crystals (certificates can be viewed), high-quality PU leather, durable heat-resistant medical mesh fabric, etc.

- Tailoring and cutting exquisitely artistic sewing.

- Strict quality control and inspection.

- Every mat assembled a handbag for storage.

- Strongly strapping the carton box for export.